Seluxit helps reducing energy waste

Do we have energy waste in the company?

The KS Group wanted to find out if there were energy optimization options for their current energy consumption. Therefore, KS Gruppen started the dialogue with Seluxit in the autumn of 2022.

Energy consumption is not a significant cost item for KS Gruppen, nevertheless, the trend in energy prices represents an increase in costs which can often be reduced.

Therefore, the challenge was to quickly find out what was profitable to look at and form an overview of the company’s operating pattern and energy consumption.

The process of Seluxit

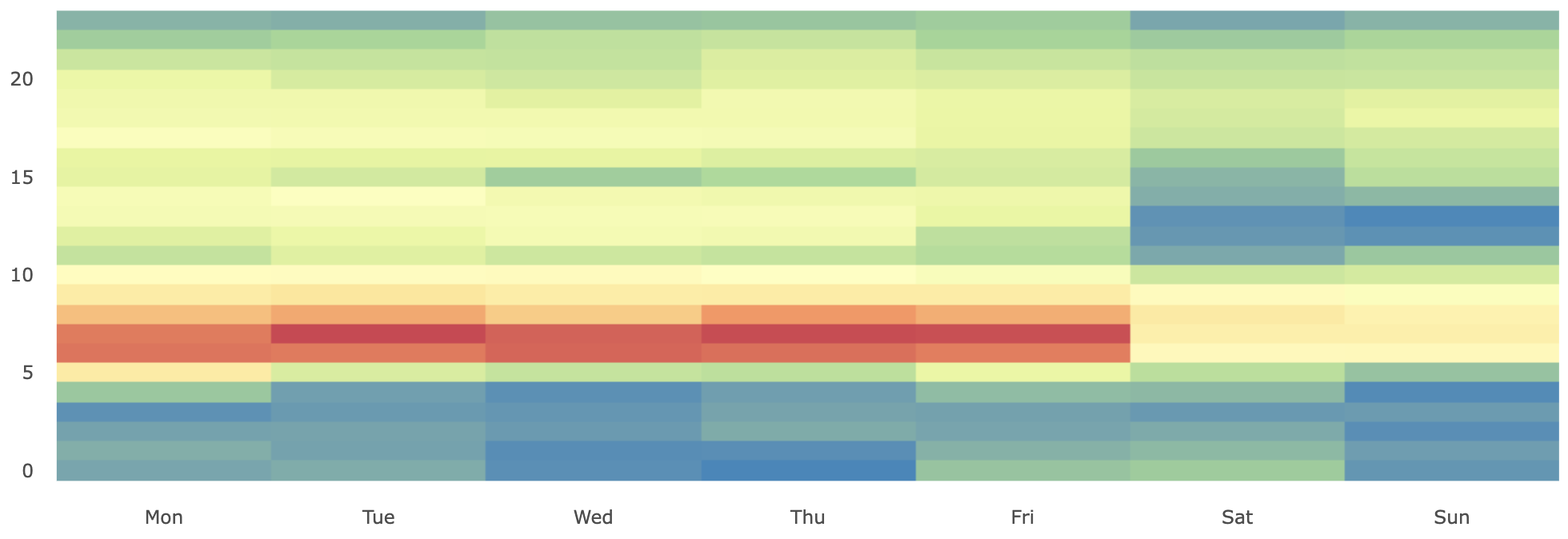

Initially, KS Gruppen gave Seluxit’s Energy Management System (Seluxit EMS) access to the historical consumption data through Eloverblik. Afterwards, a meeting was held where Seluxit could present the analysis of the energy consumption and areas of action. Thus, the basis for decisions on improvements and energy savings was discussed quickly and without much effort for KS Gruppen.

KS Gruppen initially chose to start with 2 of the identified efforts to reduce energy waste.

Steps towards energy optimization

Effort 1

KS group has information screens in the office which need to be switched on only during office hours. They are usually switched on around the clock and are only switched off manually from time to time.

With the help of smart plugs, the power consumption is measured and the info screens are switched on and off automatically.

Facts

Power savings: DKK 2,142 annually.

Repayment period: 9 months.

Estimated lifespan: 4-8 years.

CO2 savings during lifetime: at least 285 kg.

Effort 2

KS Gruppen was unaware of the electricity consumption for outdoor lighting of their buildings outside opening hours. Seluxit EMS was an eye-opener that enabled KS Group to manage energy consumption more appropriately and avoid energy waste.

Facts

Power savings: DKK 4,982 annually.

Repayment period: 1 year.

Estimated lifespan: 4-8 years.

Co2 savings during lifetime: at least 650 kg